Other than my half of our house, my

excalibur scroll saw is the most expensive thing I own (not sure our car is worth this much anymore).

Today it died!

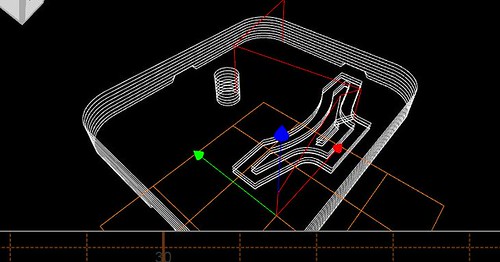

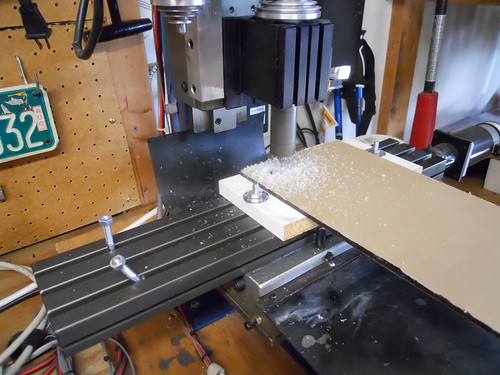

This is unfortunate, because it's my version of a 3D printer. I use it to cut all kinds of intricate parts out of all kinds of weird material(*) for this and that ... but 95% of the use is for making presents, etc. Still, the remaining 5% has saved me a bunch of monies.

(*) Wood, plywood, acrylic, metal, delrin, ...

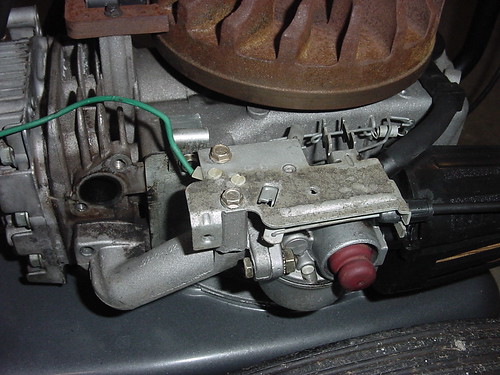

There's a rocker switch at the front of the arm (see link above) that is used to switch it on an off. I don't have a foot switch. When doing fret-work the rocker switch might be used 50-200 times for a single piece. I did notice it failing to switch on once or twice shortly before it failed permanently (it's good to pay attention), so I figured that the problem was likely the switch getting gunked up. After all, it has been used thousands of times.

The internet gave me very little to go on other than the fact that it might be the switch but more likely the fuse. I finally managed to locate the fuse (cleverly hidden underneath/behind where the power cord goes in. I checked the fuse with my multimeter. All good.

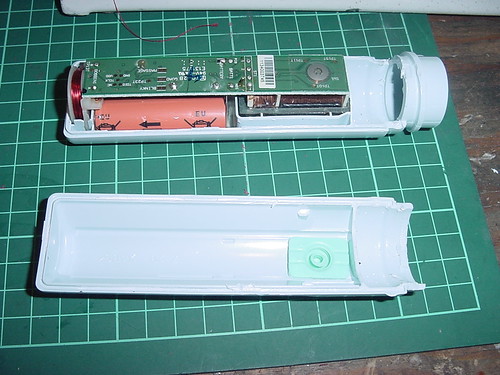

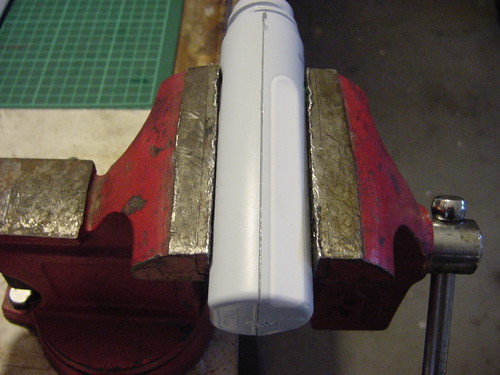

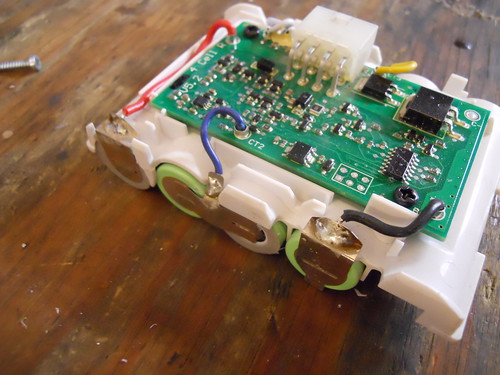

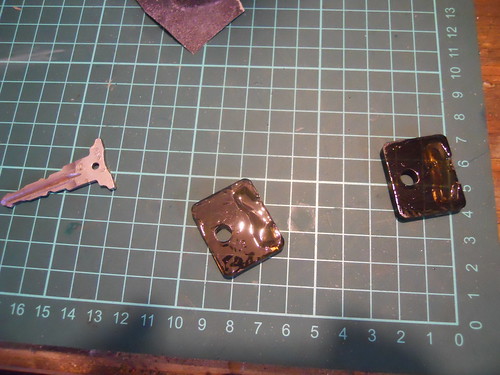

I found the manual. Since this is a pro/semi-pro machine the manual came with exploded diagrams showing all the part numbers. It was not immediately clear how to get to the switch. However, the diagram showed that some of the bolts are actually spares (THANK YOU!) and which ones were likely holding it together. Five hex screws later, I had the plastic cover of the upper arm off. The speed control is a potmeter (no surprise) and the switch is a basic switch (no surprise). Very conveniently, it was not soldered together but could be pulled off as the cables going back to the controller board were crimped onto the legs.

I wonder, are the legs standard sized? Is there are crimping tool? (Sclass, Riggerjack?) Because ...

I briefly considered shorting the switch and ordering a

foot-switch instead. I didn't wanna ghetto it because 110V runs in those wires. I could have cut the shoes off and connected them with a wire nut for a semi-permanent alteration. (I prefer my messing around to be reversible!)

Having pulled the switch out and tested it with the multimeter it was confirmed to be if not the whole problem then at least part of the problem (it's conceivable that the controller board would have been wrecked too?!).

I looked the part number from the manual up on google. There's a US supplier. $8+shipping

I looked the part number from the actual part up on ebay. Bingo! The actual part! I ordered 1 then 10 more from two different suppliers in China (hedging my bets) for $8 shipping included. Where would we be without Chinese internet entrepreneurs?

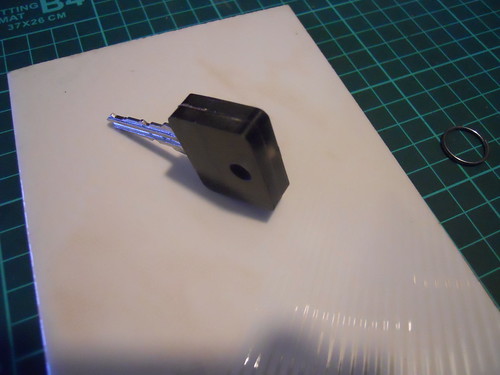

Since China-mail is slow and because I was desperate, I started inspecting the @#$@#$ switch some more. And saw a tiny hole underneath the switch where I might be able to blow in some compressed air. I always keep

one or more cans of this stuff around. Most useful aerosol ever. This was after much blowing from the top and into the switch to no effect. ("That's what she said yesterday!?") However, checking with the multimeter (lowest setting measuring resistance) again, the switch appeared to be working again, so I reinstalled it.

And success! The saw runs again.

Tools used: Google, ebay, hex wrench, multimeter, canned air, thin bladed screw driver (to pry the switch shoe/connections off), and needle nose plier (to get them back on)

So now I have 11 spare rocker switches coming in via China e-post. Maybe I can resell them on eBay for $8- a piece