Just an update on the breadmakers. I was having so much fun with my first one I bought another for $2. Panasonic brand. And boy does it have a lame recipe menu. Four settings. White, wheat, white dough, wheat dough. Seriously? It is a really well constructed machine but the software sucks. When I start the dough cycle I have to wait 30 min of "rest" time before anything happens. I think it is cycling the heater to get the water and yeast warmed up. After it kneads five minutes it shuts down for another twenty of rest. Lame! I basically want to use this thing as an automated stand mixer.

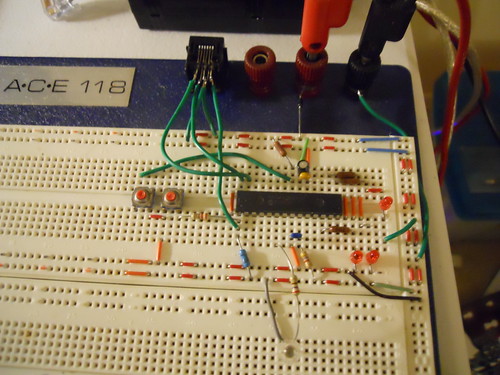

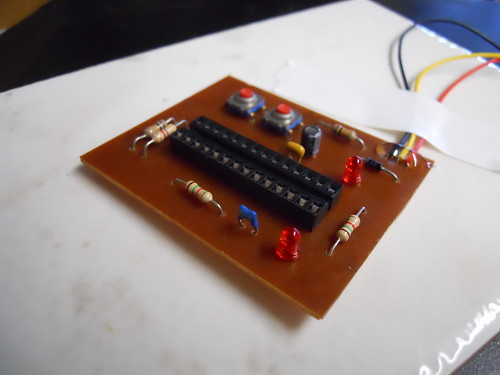

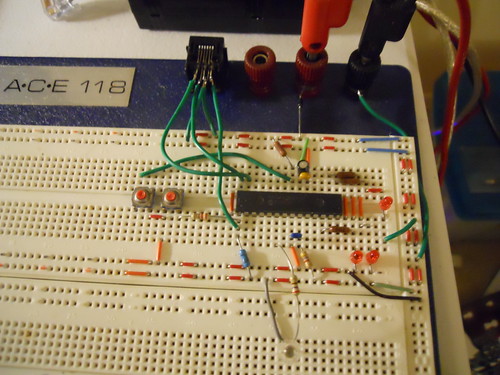

So I hacked into it and figured out how its microcontroller was activating the motor. Open collector drive that when held low stops the motor. I disconnected the line with a switch and got the impeller to spin. The problem is these machines need to spin slowly at first then speed up or else you get a volcano of flour out the top of the pan. So I made my own controller to slowly throttle up the speed as the dough kneads. I had some old microchip parts lying around. I built this. It slowly spins for a few minutes then goes hog wild. I can get instant activation with no waiting at the push of a button.

Now I needed to make it compact...or sorta compact and stick it in the bread box. I'd been watching youtube videos of people engraving circuit boards with CNC machines for awhile. So I thought I'd try it. It is pretty mindless given the prices of prototype circuit boards from China. I just quoted $2 each in qty 10 from a shop in Shenzen. Toxic waste in their drain not mine. Stink in their shop, not mine. Cheap. Shipped. Ordered online. Amazing for custom electronics.

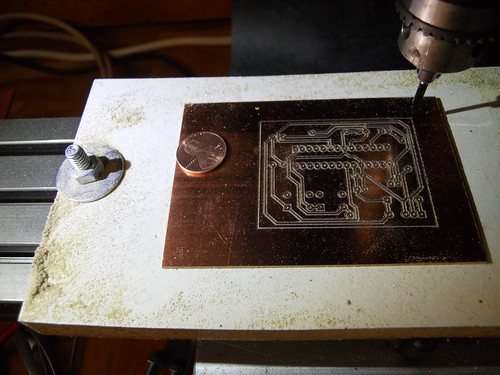

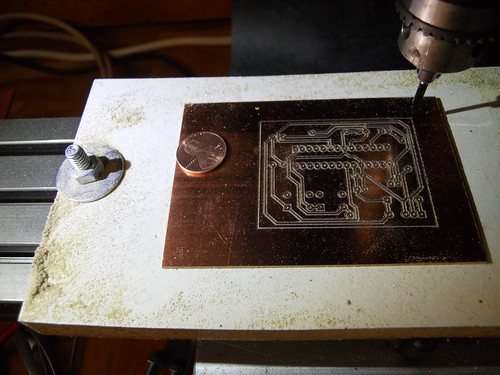

But alas, I decided I should use my CNC mill to do something useful for a change. It usually collects dust rather than create dust. After I built the thing twenty years ago, I realized I wasn't interested in machining anything. I just wanted to build the machine. So it sat.

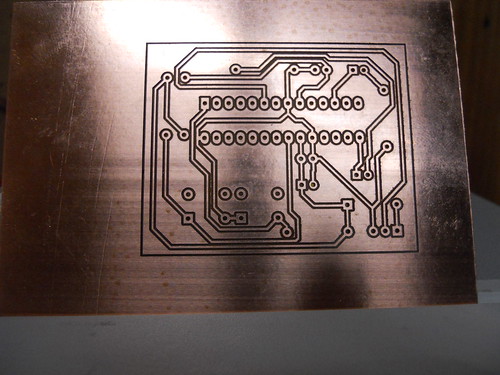

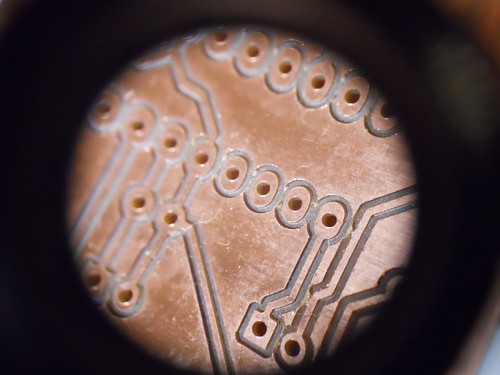

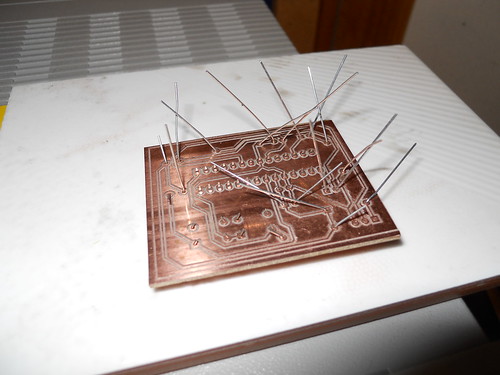

Here is the board. I used cheap FR2 bakelite impregnated paper. Modern FR4 fiberglass boards make glass powder that contaminates my work area and gets in the lead screws. So I hesitated in doing this till now. Recently I heard about the resin in paper boards and realized they're cheap (50 cts on ebay) and free of itching powder. It's a neat discovery. I also discovered a free CAM program called FlatCAM to make the isolation toolpaths using standard RS274X Gerber files from a pcb layout tool. So multiple discoveries here, fiberglass free boards, free CAM SW, cheap carbide tools.

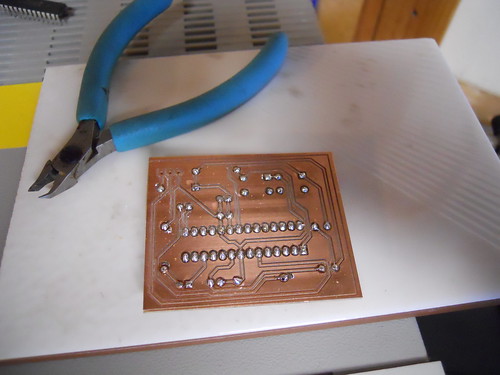

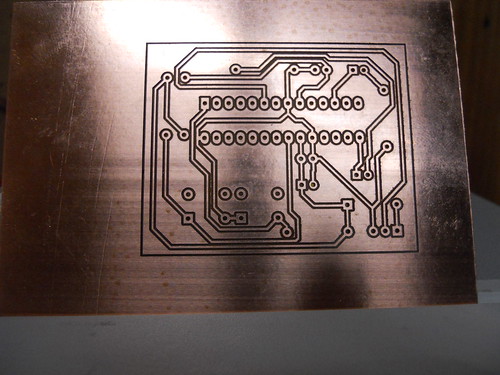

Another shot of the board:

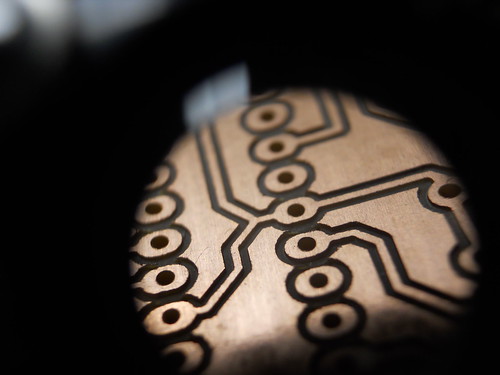

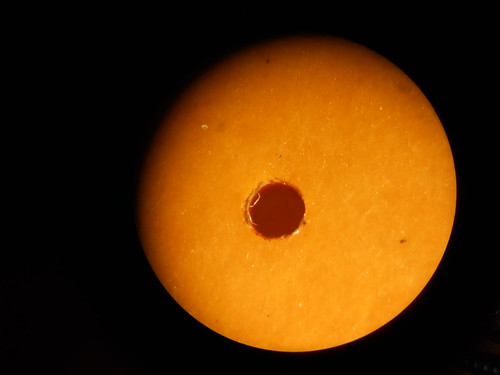

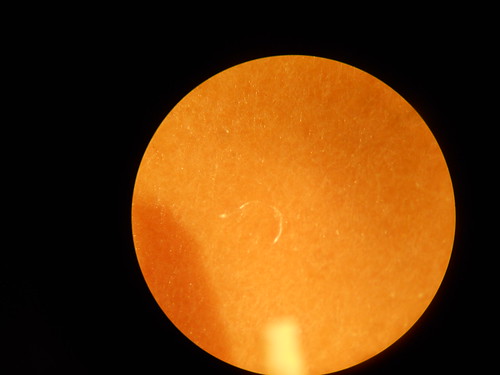

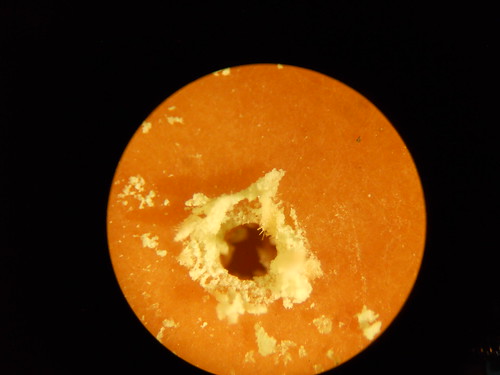

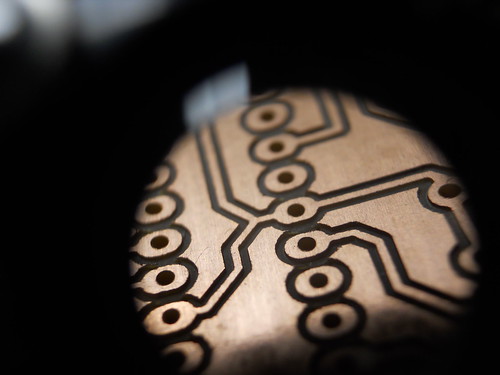

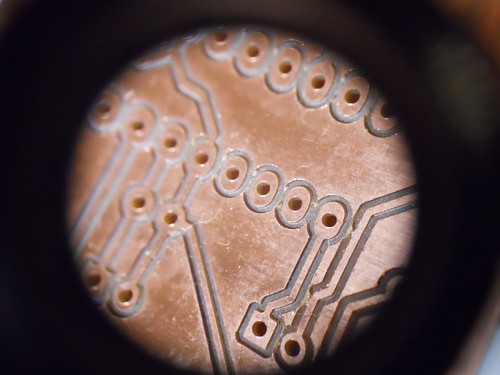

Closeup of the engraving quality. I got these really cheap gravers from China. Ten for $5. Solid Carbide V tipped cutters. I also got 10 mini carbide drill bits dia 1mm for $4. Five blank 4x5" boards for $2.50. It was cheaper than a bottle of ferric chloride. And I hate chemical waste to boot.

This may be a good trick if you want to do the prepper thing and go off the grid. Electronics offline. Just have a stash of parts, a cad/cam system, stable electrical power and some solder. No Fedex, China post or website required.

Fun fun fun in retirement. More to come.