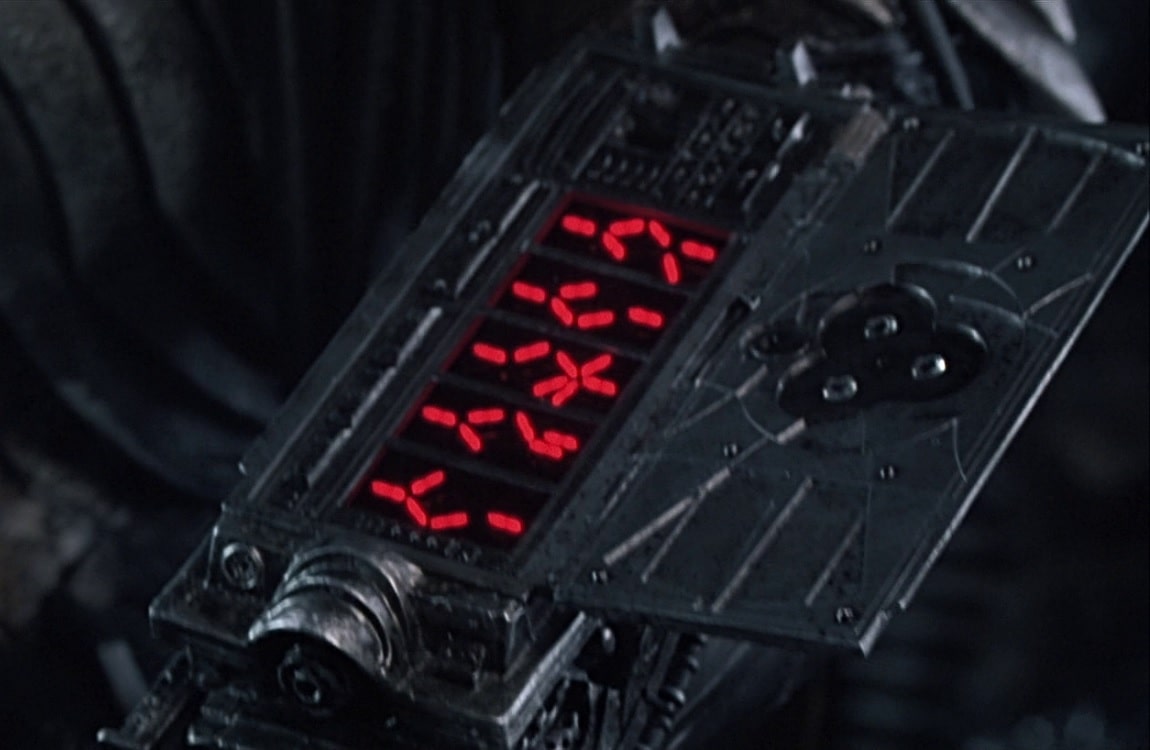

After eight years of trouble free use my LG digital smart washing machine started blinking the display randomly during washing. Sometimes it would totally go blank. Most of the time it made funny characters like the Predator wrist computer.

Symptoms were the display would start out fine then it would start blinking out as the water filled the tub. I noticed the boards got kind of steamy inside the electronics enclosure but I didn’t think much of it because the entire board assembly (two boards, display + main controls) were dipped in polyurethane potting compound. The engineers anticipated some moisture incursion.

I fiddled with the wiring with no results. Fiddling technique is just wiggle wires one at a time and look for errors. So I decided to start looking at the digital controls. The system runs two microcontrollers. One handles the wash and spin cycles and the other multiplexes the LEDs on the display. The display has enough lights on it that it needs its own controller to efficiently light it up. There’s some current control and strobing going on to minimize connections. Basically it sweeps the entire display a few blinks at a time faster than your eye can follow it. I was able to isolate the issue to this processor and board since the water valves, motor and timers all worked well without the display.

I discovered that the entire display board was dipped in urethane except for the ceramic resonator on the display driver microcontroller. I think this was intentional because the designer didn’t want the goo interfering with the resonator signal. It’s a weak high frequency pulse that can be disrupted by stray capacitance from the polyurethane around its pins. Unfortunately it was also getting a tiny amount of water vapor on the pins that was killing the resonator’s signal temporarily while filling hot water.

Once the water filled the board would defog and it would work again. It was hard to pin down with this on and off again problem.

Here is a resonator. They provide the clock pulse to the microcontroller in cheap applications that don’t need high precision timing. Like my washer. It’s the little blue thing in the center of the board on the first image above.

A little water around the wires ruins the output signal and the microcontroller loses its mind.

I smeared some dielectric grease over it and the problem went away. $1 fix from Walmart. Keeps the water out of the sensitive parts. Works now. No more blink outs. New boards are $250 each for the controls and the display. There is a person refurbishing them out there (send in your defective one and he sends you a repaired one) for $180. I suspect he’s sealing up the resonator and sending the board back out.