Make your own clock in home machine shop

Make your own clock in home machine shop

Found an interesting video series on the Clickspring channel on how to make your own clock out of raw materials in a home machine shop with a metal lathe.

I know a lot of people on the forum are interested in watchmaking and DIY metal work so I thought I would share https://www.youtube.com/watch?v=B8Y146v8HxE

I know a lot of people on the forum are interested in watchmaking and DIY metal work so I thought I would share https://www.youtube.com/watch?v=B8Y146v8HxE

-

enigmaT120

- Posts: 1240

- Joined: Thu Feb 12, 2015 2:14 pm

- Location: Falls City, OR

Re: Make your own clock in home machine shop

Impressive but funny. I mostly want a lathe to make things I can't get anywhere else, like obscure motorcycle or Napco 4WD parts. Right now a friend at work who is their machinist seems happy to tackle the odd job, but we're both retiring in a few years.

-

jacob

- Site Admin

- Posts: 16002

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Make your own clock in home machine shop

I love this stuff.

Wood clocks: http://www.lisaboyer.com/Claytonsite/Claytonsite1.htm (recently bought a scroll saw---most money I spent on a single thing for myself since 2004---and I'm still not at the level where I can cut cogs to the required precision.)

Marble machines: https://www.youtube.com/watch?v=26EE3jG5thM

Wood clocks: http://www.lisaboyer.com/Claytonsite/Claytonsite1.htm (recently bought a scroll saw---most money I spent on a single thing for myself since 2004---and I'm still not at the level where I can cut cogs to the required precision.)

Marble machines: https://www.youtube.com/watch?v=26EE3jG5thM

Re: Make your own clock in home machine shop

I designed and built this over the holidays. It took about a month to get it from inspiration to reality. Looks deceptively simple.

https://youtu.be/hC4Xu9JgdwA?si=Vv634DGBk5WXgckB

https://youtu.be/hC4Xu9JgdwA?si=Vv634DGBk5WXgckB

Re: Make your own clock in home machine shop

Great! Did you use a 3d printer or a cnc? And how did you program your machines? I am a complete novice.

-

jacob

- Site Admin

- Posts: 16002

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Make your own clock in home machine shop

Nice! Did you make your own mainspring? What did you use to make the shape of the cogs? Are they involute gears? Does it have the right gearing for hours/minutes/seconds?

I'm curious how long the plastic will last before wearing down. My first clock has started skipping beats(*) because the plywood is worn. I estimate it has run for 2000 hours or so. There's a reason why clocks (invented in the 13th century) didn't become useful until fine metal work became available.

(*) So now it runs fast by several minutes per day. Not great since it could initially be tuned to <3 second accuracy. I tried ghettoing it by making the pendulum longer and longer by that trick only works so long (literally).

(I'm still stuck getting clock2 to run consistently---the record is 6 hours. Too much friction in the deadbeat escapement.)

Re: Make your own clock in home machine shop

I used a 3D printer. I programmed it the normal way - draw parts in cad and create cam files with a slicer.

Mainspring is from a tape measure. There are sources of clocksprings all around us. I almost used a doggie leash or a lawnmower pull cord. But the tape was cheap and easy.

Gears were made in the Tinkercad gear generator. Not sure what they are but they worked. They’re cheap plastic and they will wear out. The bearings will likely go first. I have some nice brass bushings from PCB vias to bush the bearings but I haven’t bothered doing that yet.

The design was intended to be one of those demos we see in freshman physics. I only wanted to learn how to make a stable driven oscillator when I set out on this so I didn’t pay much attention to actual time keeping parameters to match up with hour minute and seconds wheels.

The whole thing is kind of a cheap 3D printed toy. It costs about $3 of filament. I wasted about $10 of filament designing the thing. That was before I figured out a way to simulate the dance of the parts on my computer to test design iterations.

Stalling means something isn’t right. I learned that the hard way over a month. I was always missing some angle or some detail and the thing would run out of energy and not sustain oscillation. All I can say is this device looks deceptively simple. Every angle and arc and dimension counts for something. You discover the issues through testing or better simulation. I was able to reduce the number of failed prototypes by 3x once I learned how to animate in CAD. The slow mo cam in my phone has been another big gift for debugging.

As I stumbled through the process I realized how good we have it compared to the Benedictine monks doing this stuff four hundred years ago. FWIW if you’re into this stuff check out the horological exhibits at the British Museum in London. I haven’t been there in years but their clock exhibit was amazing twenty years ago. High level explanations on every exhibit definitely made by nerds for nerds.

Mainspring is from a tape measure. There are sources of clocksprings all around us. I almost used a doggie leash or a lawnmower pull cord. But the tape was cheap and easy.

Gears were made in the Tinkercad gear generator. Not sure what they are but they worked. They’re cheap plastic and they will wear out. The bearings will likely go first. I have some nice brass bushings from PCB vias to bush the bearings but I haven’t bothered doing that yet.

The design was intended to be one of those demos we see in freshman physics. I only wanted to learn how to make a stable driven oscillator when I set out on this so I didn’t pay much attention to actual time keeping parameters to match up with hour minute and seconds wheels.

The whole thing is kind of a cheap 3D printed toy. It costs about $3 of filament. I wasted about $10 of filament designing the thing. That was before I figured out a way to simulate the dance of the parts on my computer to test design iterations.

Stalling means something isn’t right. I learned that the hard way over a month. I was always missing some angle or some detail and the thing would run out of energy and not sustain oscillation. All I can say is this device looks deceptively simple. Every angle and arc and dimension counts for something. You discover the issues through testing or better simulation. I was able to reduce the number of failed prototypes by 3x once I learned how to animate in CAD. The slow mo cam in my phone has been another big gift for debugging.

As I stumbled through the process I realized how good we have it compared to the Benedictine monks doing this stuff four hundred years ago. FWIW if you’re into this stuff check out the horological exhibits at the British Museum in London. I haven’t been there in years but their clock exhibit was amazing twenty years ago. High level explanations on every exhibit definitely made by nerds for nerds.

-

jacob

- Site Admin

- Posts: 16002

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Make your own clock in home machine shop

@Sclass - Something which has been on my list and which might be interesting to you too in terms of debugging is building a watch timer/time-grapher. Various internet people have attempted have attempted this with a piezo+LM386+DS3132+Arduino with various success from working to not working at all. When debugging/tuning pendulums, I still go by the sound of the tik-toks, ... tiktok---tiktok vs toktik-toktik ... making them equally spaced and equally loud. One of those is also a much faster way to fix the frequency instead of spending hours or even days making small adjustments (before 2 seconds/24 hrs differences show up).

This would make for an interesting exercise in signal-processing. There are two beats, the tik and the tok. If the tik-to-tok spacing is equal (relative), the clock is balanced (otherwise science can calculate the tilt). And if the spacing between each tik and tok and tok and tik is 60.000bpm (absolute) (adjusted for gearing) the clock keeps good time.

This would make for an interesting exercise in signal-processing. There are two beats, the tik and the tok. If the tik-to-tok spacing is equal (relative), the clock is balanced (otherwise science can calculate the tilt). And if the spacing between each tik and tok and tok and tik is 60.000bpm (absolute) (adjusted for gearing) the clock keeps good time.

Re: Make your own clock in home machine shop

I have also looked into building something like that for a long time. Got lazy though.

Some of the DIY timeographs have been successful. I recall one done with piezo guitar pickups and sound cards that seemed to have repeatable results.

There are Chinese timeographs now that go for $100-200 the last time I checked. And I think I saw a clock guy on YouTube using a smartphone app recently.

Okay, that being said yes you can build one. Something sounds wrong about using an LM386 and a Dallas RTC to make a timeograph. Wrong kind of amp. I would use a multi stage high impedance op amp for the piezo pickup. Do I need an RTC…? I usually don’t use them for things like this. I may be wrong but I don’t think this is what they’re used for. I used them to give me GMT time on a board after it was powered up for the first time in two years…not as a frequency standard driving a sampler. I would run the filtered and analog signal into the Arduino analog input and use adaptive filter to pick off the frequency. Noise is your enemy in frequency measurement schemes.

The Arduino onboard 16Mhz crystal should be fine for frequency measurement at room temp.

Ahhh yes. This one. I like this design. I even had the chips and board ready to go but I never built it.

http://www.watchoscope.com/micamp.html#amp

So if I wanted to go down this rabbit hole I’d take the three stage design with a piezo pickup. Run it to an Arduino analog channel. Use an adaptive filter on the Arduino to trim the filter to the widely input noise. Noise is the killer in frequency measurement systems. Static schemes rarely are robust.

ETA - a little snooping around online shows there’s a free SW for timing PC and Android called TGBC. Skimming it over I was able to glean that the inventor has been working on it a number of years. It’s kind of a done deal. I think I’ll buy one (pickups sold on Aliexpress for $20) just to play with it.

The signal is tricky. It has a lot of peaks to confuse a thresholding scheme. I guess if you don’t DIY it you’ll never really know how tough it is. At first glance I’m seeing 10 seconds per day of precision is 100ppm. An 18000 beat movement will have a period of 200mS. Just a guess but the impulse seen on a waveform may be 1mS so picking the wrong peak can give 1% jitter. Just a WAG but I think it’ll be a modest challenge to squeeze out 100ppm. It obviously has been done by guys like Weishi time o graphs. The TGBC looks like a much more sophisticated approach using discrete autocorrelation on a PC where you have the luxury of memory and processing power.

Some of the DIY timeographs have been successful. I recall one done with piezo guitar pickups and sound cards that seemed to have repeatable results.

There are Chinese timeographs now that go for $100-200 the last time I checked. And I think I saw a clock guy on YouTube using a smartphone app recently.

Okay, that being said yes you can build one. Something sounds wrong about using an LM386 and a Dallas RTC to make a timeograph. Wrong kind of amp. I would use a multi stage high impedance op amp for the piezo pickup. Do I need an RTC…? I usually don’t use them for things like this. I may be wrong but I don’t think this is what they’re used for. I used them to give me GMT time on a board after it was powered up for the first time in two years…not as a frequency standard driving a sampler. I would run the filtered and analog signal into the Arduino analog input and use adaptive filter to pick off the frequency. Noise is your enemy in frequency measurement schemes.

The Arduino onboard 16Mhz crystal should be fine for frequency measurement at room temp.

Ahhh yes. This one. I like this design. I even had the chips and board ready to go but I never built it.

http://www.watchoscope.com/micamp.html#amp

So if I wanted to go down this rabbit hole I’d take the three stage design with a piezo pickup. Run it to an Arduino analog channel. Use an adaptive filter on the Arduino to trim the filter to the widely input noise. Noise is the killer in frequency measurement systems. Static schemes rarely are robust.

ETA - a little snooping around online shows there’s a free SW for timing PC and Android called TGBC. Skimming it over I was able to glean that the inventor has been working on it a number of years. It’s kind of a done deal. I think I’ll buy one (pickups sold on Aliexpress for $20) just to play with it.

The signal is tricky. It has a lot of peaks to confuse a thresholding scheme. I guess if you don’t DIY it you’ll never really know how tough it is. At first glance I’m seeing 10 seconds per day of precision is 100ppm. An 18000 beat movement will have a period of 200mS. Just a guess but the impulse seen on a waveform may be 1mS so picking the wrong peak can give 1% jitter. Just a WAG but I think it’ll be a modest challenge to squeeze out 100ppm. It obviously has been done by guys like Weishi time o graphs. The TGBC looks like a much more sophisticated approach using discrete autocorrelation on a PC where you have the luxury of memory and processing power.

Re: Make your own clock in home machine shop

@Jacob if you haven't yet heard of the musician and musical instrument engineer "Wintergatan," you might enjoy https://www.youtube.com/watch?v=-gPVvoIEw0w

Re: Make your own clock in home machine shop

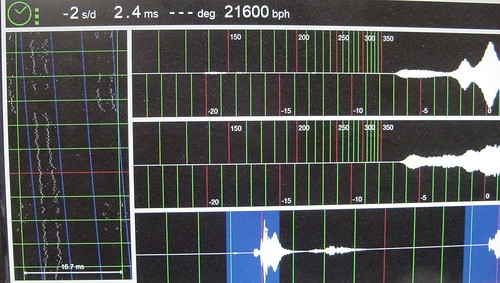

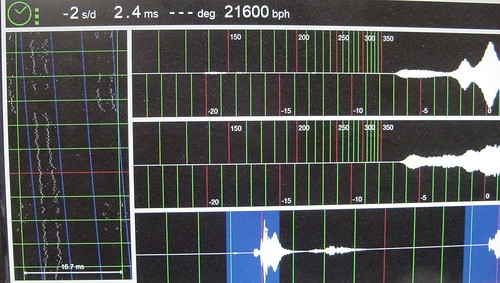

So I received my watch timing machine from Aliexpress. It works very well on watches which is what the software was designed for.

Not sure how it will work on DIY clocks. The free open source SW has some autodetect frequency feature which may not work on low frequency clock movements. Haven't played enough with the SW. It looks like it can read an arbitrary low frequency like 0.5 Hz but I'm only guessing. There seems to be an audio out jack (likely for headphones) that can likely be used as an input to some other timing device if you desire.

For fun I dropped a watch I was given back when I was a high school student. Mechanical. Cheap. It cost my father $5 IIRC. the TG sw showed it was 31 seconds a day slow. I was able to get it to around 2 seconds a day slow using the sw and adjusting the regulator. It seems somewhat stable. Not bad for a $18 watch timeographer.

Thought I'd share it. Not sure what to do now. I checked over my dozen watches in my collection. They are anywhere from 20 seconds to two minutes off per day. I'm kind of out of the hobby now or I'd tear down some of them and lubricate their bearings. I don't really care anymore. Somehow carrying an iphone has killed all my interest in mechanical wristwatch accuracy.

Anyhow the device is a great deal. It's too cheap to make me want to DIY. I was able to make my watch significantly more accurate. I guess it was worth $18 of entertainment. About the same joy as I get on a movie ticket.

Not sure how it will work on DIY clocks. The free open source SW has some autodetect frequency feature which may not work on low frequency clock movements. Haven't played enough with the SW. It looks like it can read an arbitrary low frequency like 0.5 Hz but I'm only guessing. There seems to be an audio out jack (likely for headphones) that can likely be used as an input to some other timing device if you desire.

For fun I dropped a watch I was given back when I was a high school student. Mechanical. Cheap. It cost my father $5 IIRC. the TG sw showed it was 31 seconds a day slow. I was able to get it to around 2 seconds a day slow using the sw and adjusting the regulator. It seems somewhat stable. Not bad for a $18 watch timeographer.

Thought I'd share it. Not sure what to do now. I checked over my dozen watches in my collection. They are anywhere from 20 seconds to two minutes off per day. I'm kind of out of the hobby now or I'd tear down some of them and lubricate their bearings. I don't really care anymore. Somehow carrying an iphone has killed all my interest in mechanical wristwatch accuracy.

Anyhow the device is a great deal. It's too cheap to make me want to DIY. I was able to make my watch significantly more accurate. I guess it was worth $18 of entertainment. About the same joy as I get on a movie ticket.