Hi JP. No, that knife is really sharp. It'll go right through wax. It gets honed two times on average during a meal.

The original milk jug scabbard started to drive me nuts because it sucked. Nothing like seeing something you made everyday that happens to suck. Milk Jug Scabbard REV 2. This is hot off the bench.

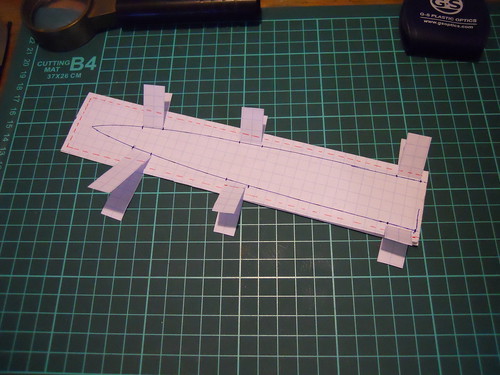

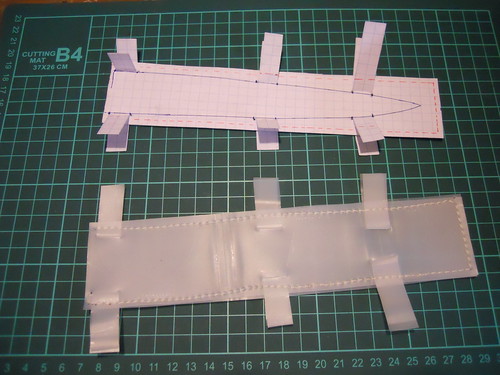

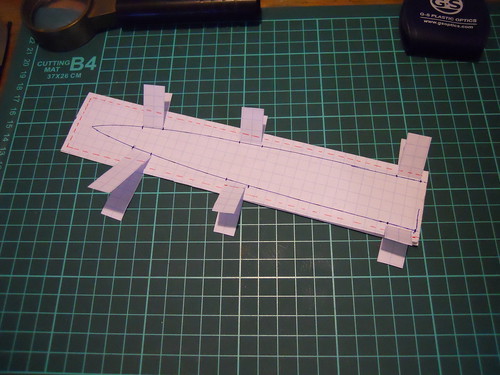

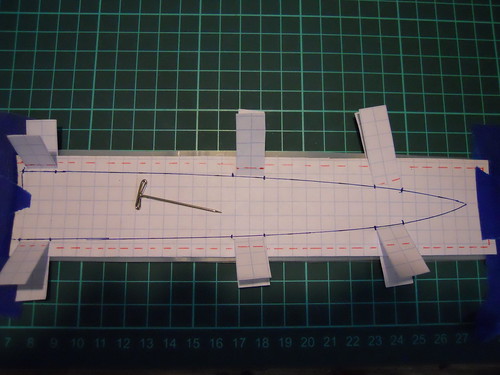

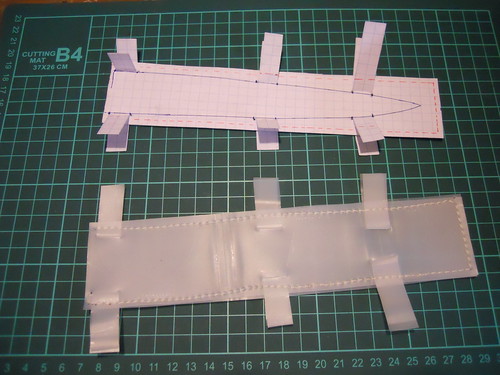

I was first thinking I should drill some holes in the scabbard and loop some zip ties through along the blade's edge. Or maybe use some aluminum pop rivets. But then I thought I already have plastic strips in the milk jug. So the idea was to make some slots just along the blade and loop some milk jug material through then sew it down with the stitching far away from the blade - protected from the razor edge. I wanted some ideas with tough milk jug armoring, here it is. Conceptual model here. I noticed in my real leather knife sheaths, the center ridge in the sheath not only stops the blade tip, it distributes the load of the knife over the length of the sheath so the pressure at one support point isn't too high. Kind of like sleeping on a bed of needles. So I put these straps through at three places.

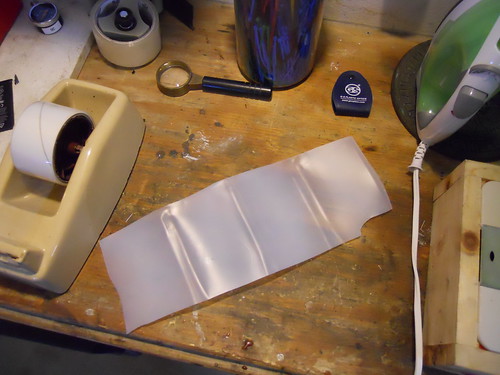

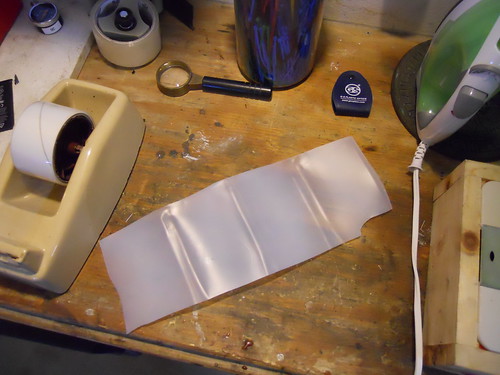

Now to harvest some material. I just finished off a jug this morning making lattes. I cut the center and then use an iron to flatten things out a bit. It is alot like working leather.

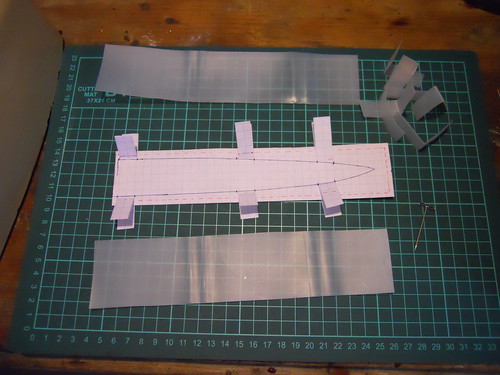

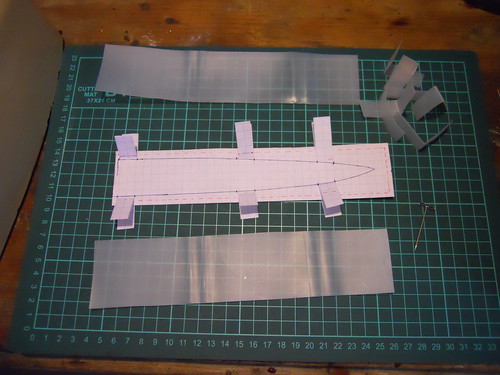

Cut the pieces from my pattern. I used a rotary cutter. Amazingly it went right through. The plastic is slippery unlike leather or fabric so you have to hold it down while not cutting off your finger tips. I'm still on my first cutter blade. I'm still blown away by the thing. It's like cutting pizza.

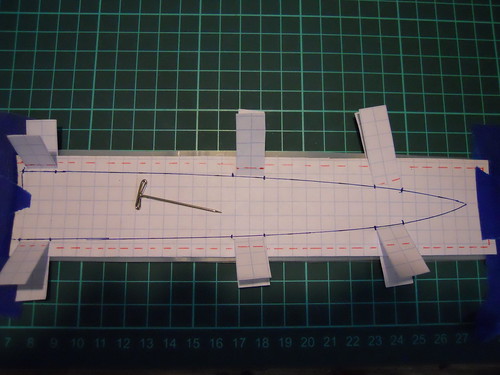

Now I tape everything down to my cutting pad. My new favorite cheap punch is a T pin. I made some registration holes to locate the straps. They have to be precisely placed so the blade comes to rest on all of them simultaneously. I don't want one strap getting the first stab as I sheath the knife. Once I know where everything goes, I can make little slits with a craft knife.

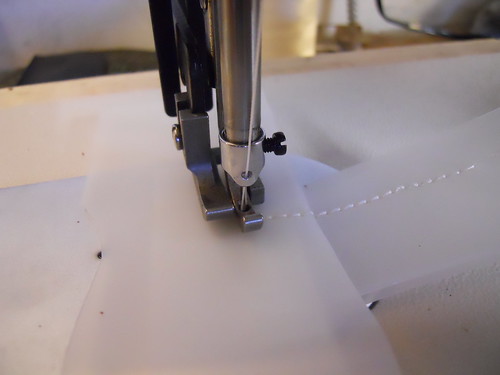

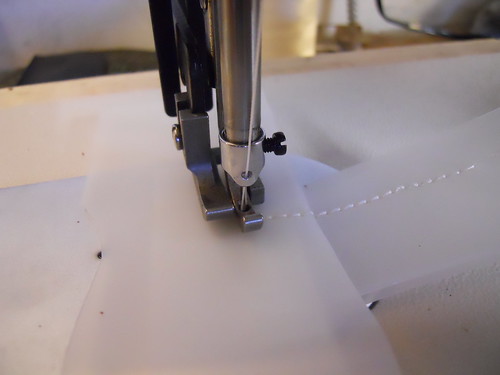

Setup the machine tension. This one will be a little tricky because it has to handle two layers of milk jug then instantly transition to four layers without skipping a stitch. Looking good.

And here it is. I wavered a little on the stitch. That milk jug is slippery. But it will work! Now I just need to trim it up.

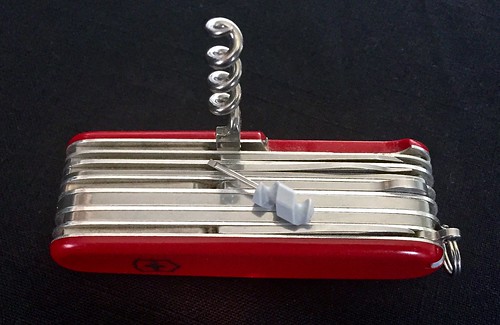

Hey, now this is an item I don't mind seeing and using everyday. Satisfactory.