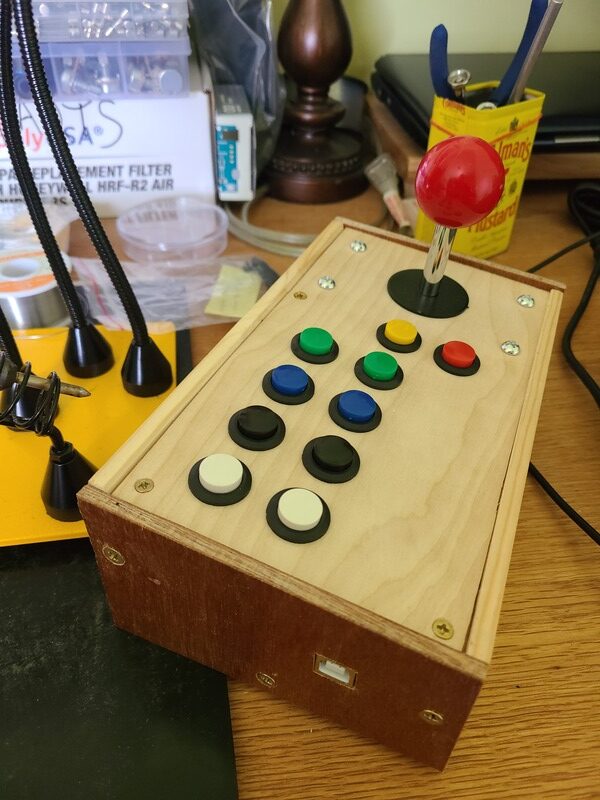

Tying up some loose ends I figured I could (and therefore would) make an arcade controller to bring

the project in

this thread to full circle. The box originated in the

AQI project. Some parts were surplus (buttons) and some were misguided "first effort" from first attempts (the zero delay encoder) at

this project/direction. Here's to closing the loops!

Most ingredients were already on-hand (the buttons and the "zero delay usb encoder" (the circuit board, google it)). All I needed to buy was the stick. Technically, I maybe/coulda made my own. Blade switch sticks were not unusual back in the 1980s.

Pro tip! To install buttons, etc. into a shoe box, I use a Forstner drillbit that's 1/8 smaller than the diameter of the button. For example, my buttons are 5/8OD (outer diameter), so I drill 1/2 and push the buttons trough as the cardboard gives in/for the threading. This solution holds for quite a while. To install in wood (or metal) use the exact diameter, ie. 5/8".

As you see, it's pretty simple. No soldering required. For an actual non-cardboard final design box, my preferred design-method is to put the circuit boards upside down on the top. Here it would sit to the left. This didn't happen here, but it did happen

there.

Note how I put the PCB on standoffs on top of a piece of plywood. What's worked for me is to buy some M3 plastic standoffs and then use a tap&die set from Harbor Freight to tap into the plywood. Tapping perpendicularly into plywood is easy and it holds. (Conversely, going along the plys does not work! I tried.) So I drill some holes and use the tap, here M3x0.5. I recommend going slightly smaller than "metal" before tapping. No need to go 1/2 forward--1/4 back to clear for wood. Better to just push ahead all the way through.

However, given all this is non-conductive cardboard, you don't need to if you're just going to ghetto it/okay with letting it all hang loose inside the box.

Also note how I reinforced the stick mounting with an extra piece of cardboard. The stick is attached to the top of the cardboard box using a $5 nut/bolt set from harbor freight.

On the software side, Win10 immediately recognized this contraption as a generic (HID controller) USB stick. The zero delay encoder is very common (google MAME/JAMMA) and widely supported by software after 2015ish. I can now enjoy a couple of games from my younger years, specifically

https://store.steampowered.com/app/3208 ... d_Edition/ and

https://store.steampowered.com/app/2622 ... Guns_Gold/

Presented as a $25 alternative to the zipstick generation (if you know what that is, you're older than 45)... before WASD became a thing.

Also, the red knob screws on. It's an M6 thread in case you want to replace it with something else. (Tap 6mm into your own design, maybe something turned on lathe?) In any case, I highly recommend afixing it with some BLUE Loctite once installed. Otherwise, it gets annoying very quickly.

Add: Everything here is momentary on-off contacts including the stick ... (on) ... so it's possibly to substitute in whatever you want or have.

Add2: I use a power drill with very light pressure to make the holes perfectly round. A box cutter/knife probably works too.