@jacob

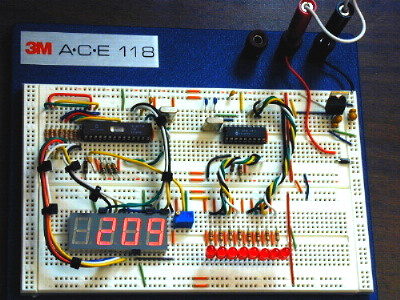

that first image looked familiar. I built that board in grad school. Not a good example because it is 100% built on a breadboard with through hole components. It naturally lays out on a breadboard. You can pick up some ideas like twisting signal wires (in different colors) together but really your design in the second photo is a different animal. I think I posted that to show how you can use precut jumpers to cleanup a breadboard. It makes it easier to transition to a PCB because it kind of looks like the PCB. Clean wiring facilitates debugging.

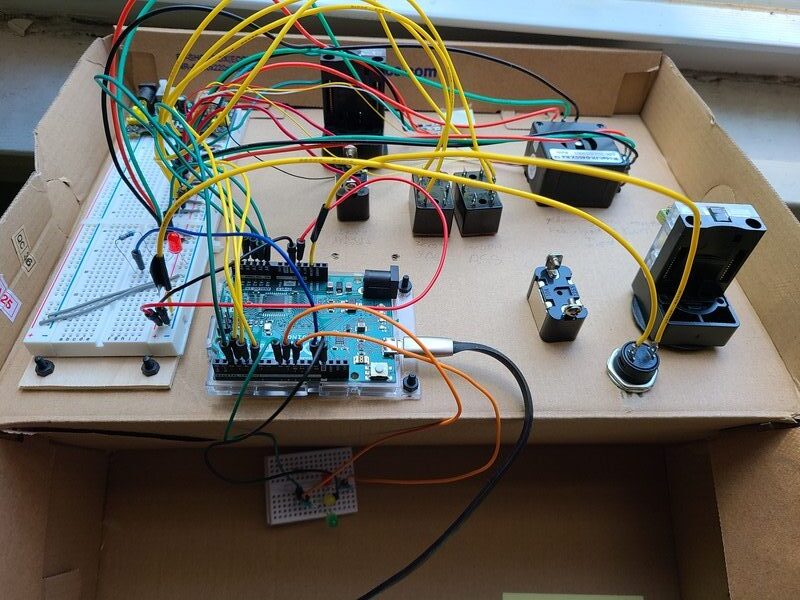

What you need to look at is this. Scattered modules with various connections. Plugs mounted through a front panel. Modules strapped down to a chassis and interconnects. Color coded wires for signals. All high speed connections twisted up for signal integrity. Zip ties every inch (don’t be stingy) and power on the red black zip line.

Yes that was kind of art and science. This is my CNC box. I built this decades ago. I had access to the HP Labs stockroom back then. I guess I didn’t feel bad about using their zip ties and wire like water.

What I don’t show is what comes first. No wires. Lay out all te components first. Then wire point to point with perfect lengths. I trimmed the wires several times to get the runs to obtain perfect length. Also I used zip ties as temporary place holders. I likely used 4x the number of zip ties than what you see. There is a pile of clipped ones on the floor along with lots of wasted wire. I likely used 2x the wire you see here. I start at a connector and run a long run (2x the expected length) of wire bundling and twisting and fitting it one Inch at a time. And I work my way across to the destinations splitting branches and combining tributaries as I go while zipping every Inch. This way you clear up all the unwanted slack as you work your way across the instrument. You keep clipping the ends back till you get nice matching lengths routed exactly the way you want.

The art is the bending, twisting and bundling. The science is when you twist, when you isolate and what you bundle with what. It’s your design so you’ll know what wire can and can’t run parallel with one another.

It takes some practice to do this well. Tear things apart and look at how they’re harnessed. Then try some baby steps. Start at one of your switches and work your way across while joining the bundles tightly behind you.

This design started out with bolting down all the modules and mounting all the connectors in logical places. It took a few hours to get the wiring in as I wanted it. A testament to its proper construction is I used the CNC today and the electricals work flawlessly just like they did in 2000. The machine survived a tear down and reassembly when I moved from Silicon Valley to Irvine. It just plugged together and it worked without a hiccup.

This is not easy. I built a lot of garbage hardware before I made bankable product.

@dutchgirl there are softwares for doing this. Zuken is currently a good tool. Ten years ago I used Altium and CablEquity which had fewer features but are cheaper. These tools start with a wiring diagram and finish with predicted lengths of conductors, net lists, BOMs, nail board drawings for assembly and testing. Still I start with a prototype then I document the harnesses after I build them.

Nail board. Work harder work faster.

Hats off to Riggerjack for basically saying the same thing in ten lines.