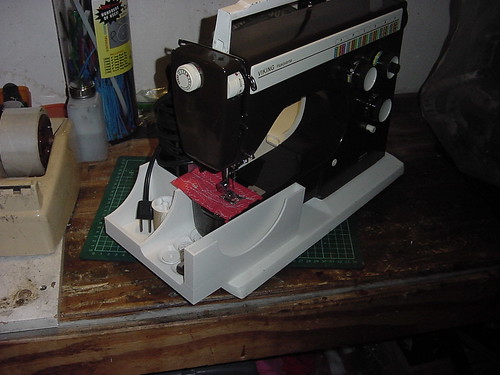

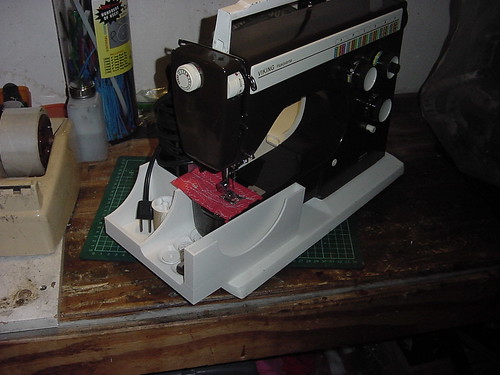

I recently bought a Husqvarna Viking 6440 sewing machine. I restored it and it works well. It took another couple of days in the shop to figure out some more subtle and elusive issues but eventually I figured it all out. Right now it doesn't have the accessory box. I have the outer carrying case but the internal box that fits under the arm was missing among other things. It's kind of a nice thing to have to keep the bobbins and notions tidy.

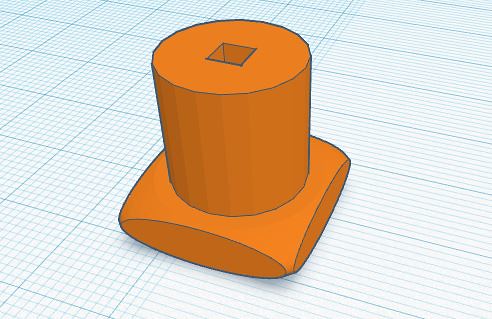

The bobbins are Husqvarna only and it only came with one. So I designed one in 3d cad and printed a handfull. The bobbins cost over $1 each in metal but I spent about $0.04 ea of filament to make my own. I just didn't feel like spending any more money on this machine. I have $40 invested in it as of now.

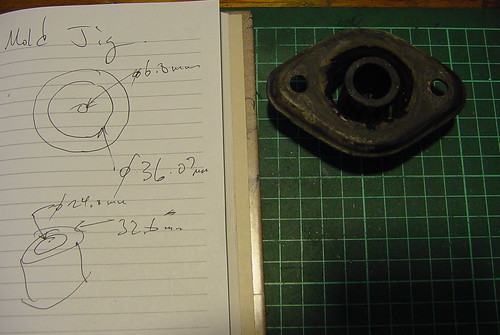

Checking ebay, the official accessory box costs anywhere from $25 and up plus shipping. Some idiots want $100 for a box that is made of 40 year old plastic that will crumble apart on arrival. This is what it looks like.

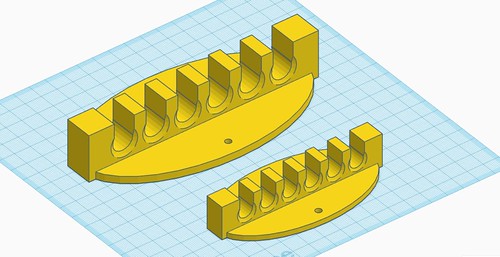

Fits under the arm of the machine and the outer machine carrying case fits over the whole thing. I wish it came with this box but it looks easy enough to make on the 3d printer. It took under an hour to design this. My own twist on the old design. I figured it would be easier to print. It took 22 hours and used 200g of PLA filament. This cost me about $5 not counting electricity.

Here is some detail of the hidden bobbin carrier that fits under the sewing arm. The beautiful cutouts literally take minutes to carve out of the model using Tinkercad. They're just simple spheres and cylinders.

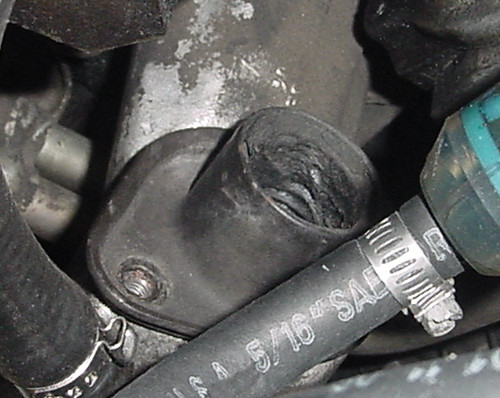

Here it is installed under the machine. There is a slot for the owner's manual up front.

Out back there is a holder for Husqvarna's giant foot pedal control. Keeps that tidy and together with the machine. You don't want to get these separated. The foot pedals for these old machines are getting hard to find even on ebay.

The whole thing fits under this tidy case that clips over the top of the machine. I'm really happy with the outcome. Of course if I printed it again I could make it a bit better but realistically this will perform the job.

This is kind of my drug hit that keeps me going. I never gave a lot of thought to what I'd do once I didn't have a job. I rehearsed my resignation mentally for years but I never rehearsed the eight years that would follow it.

I've met a lot of real retirees over the years and seen their crisis as they went from 65 to 75. A few neighbors in my old home town would make little steam engines with scraps of metal in their garages. Beautiful things. They were retired engineers. I didn't understand what they were trying to do at the time...it seemed like killing time. The projects had to be cheap and time consuming. I'm afraid I'm there now. I ran so hard to finish early and I now act like a 70 year old in my workshop. But I'm only 51. For the first time in my life I'm actually afraid of acting older than I actually am.

Just thinking out loud. What else would I do for direction? I'm like an engineering engine that isn't hooked to anything anymore. If I keep spinning with no load I may just self destruct.

COVID has made this all more difficult. My regular routines have really been cut off the last eight months.

Hey, just thinking out loud. Retirement. Hmmm. I'm wondering if I managed to escape the slaughterhouse and just wandered off into the woods without a plan just to wander aimlessly for an extra twenty years.