Heat resistant gloves and melting plastic

-

jacob

- Site Admin

- Posts: 15975

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Heat resistant gloves and melting plastic

For touching dry sticky stuff at the boiling point of water (melted plastic). So far I've tried to double up on gardening gloves, but it's not very flexible. Any better ideas?

Re: Heat resistant gloves

Don’t touch it. Use a tool to sub for your fingers. Explore options used by candy makers.

Re: Heat resistant gloves

I use welding gloves for handling hot materials. But steel is not sticky, so I am not sure if this works well for plastic...

-

Riggerjack

- Posts: 3191

- Joined: Thu Jul 14, 2011 3:09 am

Re: Heat resistant gloves

Silicone oven mitts?

Re: Heat resistant gloves

For your boiling point of water problem I’d suggest a pair of 4 mil nitrile rubber gloves over a pair of thermal glove liners. You can still have some sensitivity while limiting thermoconductivity. They come in all materials like polyester, silk and wool. I think if they can keep you warm they can probably keep you cool and the rubber will keep the hot water out.

-

basuragomi

- Posts: 420

- Joined: Tue Oct 15, 2019 3:13 pm

Re: Heat resistant gloves

I use silicone oven pinch-type mitts for handling hot candy. I get about 20 seconds of working time on ~120C material before I have to stop and let the gloves cool down. Silicone plus insulated liner allows basically indefinite work. Gloves tend to be textured however which can lead to undesirable imprints. What works best is just sticking the whole melted mass on a smooth silicone baking sheet and folding the sheet back and forth to homogenize, stretch, pile up, etc. mixtures.

-

jacob

- Site Admin

- Posts: 15975

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Heat resistant gloves

I've been using pigskin gloves w/o liner. It gives me about 10 seconds. The conductivity of the plastic is < than the metal plate it's on. Stickiness solved with baking paper.

Re: Heat resistant gloves

That sounds good. I think TIG welders gloves are pigskin. The sensitivity can be quite good. I had a pair that fit snuggly and allowed a lot of tactile feedback to the filler wire. The catch was they were a bit pricey like $30 back in 2000.

Are you recycling plastic by any chance?

Are you recycling plastic by any chance?

-

jacob

- Site Admin

- Posts: 15975

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Heat resistant gloves

Yes, #2. At this point I'm more at the "forging and machining"-stage than the "casting"-stage.

I press it into thin bricks, maybe 1/4"-1/2" thick. Then I can drill holes in it and use the scroll saw.

I've yet to make more than a soap mold for DW. BTW, these are often 3D printed and sold online for $10-20.

I press it into thin bricks, maybe 1/4"-1/2" thick. Then I can drill holes in it and use the scroll saw.

I've yet to make more than a soap mold for DW. BTW, these are often 3D printed and sold online for $10-20.

- Alphaville

- Posts: 3611

- Joined: Thu Oct 03, 2019 10:50 am

- Location: Quarantined

Re: Heat resistant gloves

it's funny that when you search how to recycle #2 hdpe the instructions are where to dump it. as if placing it on a bin was a chemical process.

curious about the how-to. shred + melt? links to instructions on the actual process would be appreciated...

curious about the how-to. shred + melt? links to instructions on the actual process would be appreciated...

-

jacob

- Site Admin

- Posts: 15975

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Heat resistant gloves

https://www.youtube.com/watch?v=-igxhoGEQFU and many more like it.

I think it was a thing in the maker community a few years ago.

I think it was a thing in the maker community a few years ago.

Re: Heat resistant gloves and melting plastic

Nice. I always wanted to try this. Follow up with your end uses.

-

white belt

- Posts: 1457

- Joined: Sat May 21, 2011 12:15 am

Re: Heat resistant gloves and melting plastic

@Jacob/Sclass

I wonder if you could use those plastic bricks in a 3D printer? In theory, then you could pretty much make any object out of scrap plastic (without a printer you can already make many objects by hand). Maybe that’s what you’re eventually working towards.

I didn’t know melting plastic to re-use it was even possible, so I will have to explore this more. The fact that I could possibly make certain specialty plastic parts/tools could be a game changer in terms of pro-longing the life of a system. Also it means I could make plastic objects in a post-apocalyptic future since the supply of waste HDPE already on the planet is virtually limitless.

Quick Google search says maybe possible: https://www.sk3tchup.com/2017/09/3D-Pri ... e.html?m=1

I wonder if you could use those plastic bricks in a 3D printer? In theory, then you could pretty much make any object out of scrap plastic (without a printer you can already make many objects by hand). Maybe that’s what you’re eventually working towards.

I didn’t know melting plastic to re-use it was even possible, so I will have to explore this more. The fact that I could possibly make certain specialty plastic parts/tools could be a game changer in terms of pro-longing the life of a system. Also it means I could make plastic objects in a post-apocalyptic future since the supply of waste HDPE already on the planet is virtually limitless.

Quick Google search says maybe possible: https://www.sk3tchup.com/2017/09/3D-Pri ... e.html?m=1

-

jacob

- Site Admin

- Posts: 15975

- Joined: Fri Jun 28, 2013 8:38 pm

- Location: USA, Zone 5b, Koppen Dfa, Elev. 620ft, Walkscore 77

- Contact:

Re: Heat resistant gloves and melting plastic

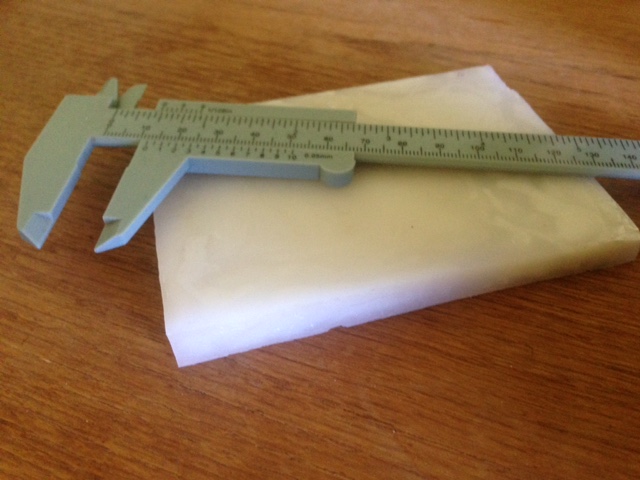

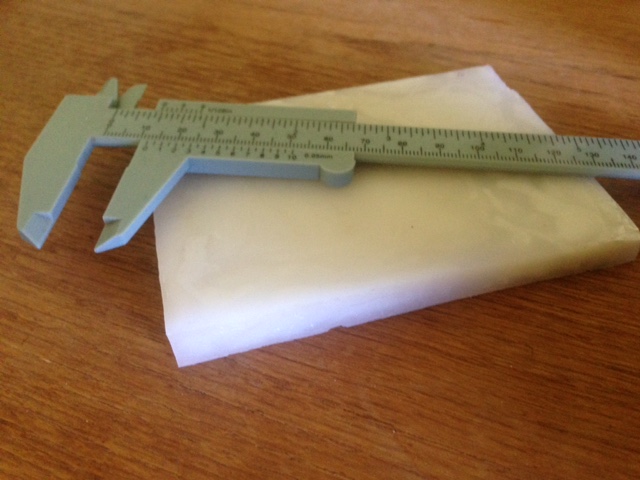

Here's an "ingot". I was aiming for 3/8 thickness but it's more between 5/16 and 7/16. Need to figure out a better way to control the press. Since this might be surprising (it was to me), once you thicken up the plastic, it really stiffens up. One project might be a letter opener. I think it could also be used for small machine parts once I figure out the thickness issue. I'm reluctant to gunk up my woodworking tools with too much plastic.

"Cold forging" might be the answer. That's something you can't do with wood. Any ideas for a "proof of concept"? Stuff/parts I could make?

Also learned in the most annoying manner that not all #2 is the same. For this "ingot", it was oatmeal lids and ethanol containers. The former has a lower melting point than the latter You can see the two different materials on the RHS of the pic.

You can see the two different materials on the RHS of the pic.

Bench chisels are great for cleaning up rough edges. Carving tools are probably (I don't have that many) the best way to work the material, so basically think of "what you can do with HDPE" as "what would a carver/turner with wood".

"Cold forging" might be the answer. That's something you can't do with wood. Any ideas for a "proof of concept"? Stuff/parts I could make?

Also learned in the most annoying manner that not all #2 is the same. For this "ingot", it was oatmeal lids and ethanol containers. The former has a lower melting point than the latter

Bench chisels are great for cleaning up rough edges. Carving tools are probably (I don't have that many) the best way to work the material, so basically think of "what you can do with HDPE" as "what would a carver/turner with wood".

- Alphaville

- Posts: 3611

- Joined: Thu Oct 03, 2019 10:50 am

- Location: Quarantined

- Alphaville

- Posts: 3611

- Joined: Thu Oct 03, 2019 10:50 am

- Location: Quarantined

Re: Heat resistant gloves and melting plastic

i should add i read somewhere that hdpe can be recycled "up to 10 times" so maybe the different subspecies are at different phases of the recycling churn, e.g. "virgin" and "reprocessed". i don't know that a piece of plastic could be tracked 10 times over the cycle so i'm assuming just 2 kinds. but really i have no idea, i'm no chemical engineer, this is just a guess. could be they are molded by different processes also, or have additives.

i feel like kant when he philosophized about why starts didn't fall into each other, while lacking awareness of the big bang, except i realize my own futility and he didn't realize his

see: https://en.wikipedia.org/wiki/Universal ... he_Heavens

anyway, is there a chemical engineer in the house? i know we had a future one recently, but don't know if we have a current one.

eta: search.php?keywords=%22chemical+engineer%22

there've been a few...

ok here's the 10x plus some info: https://www.azocleantech.com/article.aspx?ArticleID=255

eta2: maybe if we can't sort the science easiest thing would be to just melt like with like ¯\_(ツ)_/¯

i feel like kant when he philosophized about why starts didn't fall into each other, while lacking awareness of the big bang, except i realize my own futility and he didn't realize his

see: https://en.wikipedia.org/wiki/Universal ... he_Heavens

anyway, is there a chemical engineer in the house? i know we had a future one recently, but don't know if we have a current one.

eta: search.php?keywords=%22chemical+engineer%22

there've been a few...

ok here's the 10x plus some info: https://www.azocleantech.com/article.aspx?ArticleID=255

eta2: maybe if we can't sort the science easiest thing would be to just melt like with like ¯\_(ツ)_/¯

Re: Heat resistant gloves and melting plastic

Additives aside, HDPE is not a molecularly homogeneous material - it is a mixture of hydrocarbon chains of varying lengths and degree of branching. HDPE's physical properties, e.g. "melting point", depend on the length and branching distributions of the PE molecules it is composed of.

Imagine a ball of iron chains. It would be very different to try and change the ball's shape when the individual chains are made with three links vs. 10 links vs. 10 links with two-link branches on every second link, etc. you get the idea.

Different batches of HDPE would give a material of uniform softening temperature, once mixed properly, although getting it hot enough to do that is perhaps not easily done.

Imagine a ball of iron chains. It would be very different to try and change the ball's shape when the individual chains are made with three links vs. 10 links vs. 10 links with two-link branches on every second link, etc. you get the idea.

Different batches of HDPE would give a material of uniform softening temperature, once mixed properly, although getting it hot enough to do that is perhaps not easily done.

Re: Heat resistant gloves and melting plastic

I stumbled across this in a trade rag. Very tempting to build one.

The homemade filament will probably produce low quality prints. Single use plastic upcycling is a really tough problem to solve.

https://www.sciencedirect.com/science/a ... 7218300208

The homemade filament will probably produce low quality prints. Single use plastic upcycling is a really tough problem to solve.

https://www.sciencedirect.com/science/a ... 7218300208