Took me a bit to think understand what is going on here. GND is likely hard because the board may have extra copper plane around the ground to handle the heavy return current. It likely has more thermal mass. Physics. You want to sink away electrons at that point as to not create transient potentials…and this has the side effect of not letting heat build up there either. You need more heat flux on your iron. Either your tip has poor conductivity or your iron cannot dump heat in fast enough. Likely the tools not the work man. More powerful soldering iron needed. The LED board designer has given you a highly conductive ground which you have now connected to a high impedance daisy chained connection…which brings us to this.jacob wrote: ↑Tue Oct 24, 2023 2:05 pm

I spent around 10 minutes trying and retrying soldering the pins on. GND was the worst!, what an exercise in frustration! As a good^H^H^H^Hbad workman, I blame my tools.

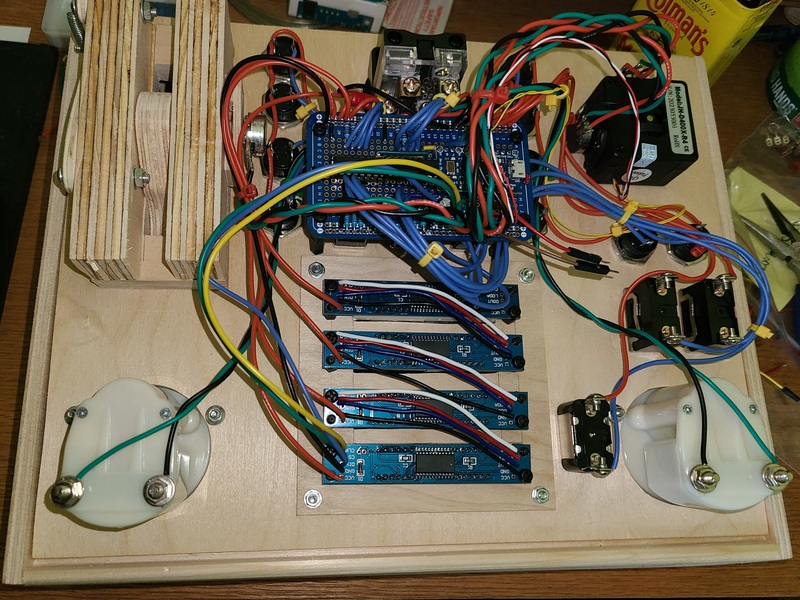

And wire the power in parallel from an external supply. This should allow me to keep the diodes w/o suffering the foolish "safety" voltage drop. Also, I can wire in the capacitors off of the board.

That might be the source of their digital noise. My daisy-chain is soldered all the way through.

So the noise on LEDs comes from exactly this. The surges in power tow your power down. The same power you are using to reference your precision analog voltages you divide to make your potentiometer voltages that you are sampling. They will also make your grounds bounce up and down as the electrons try to find the drain and make the ground level temporarily rise. Ground bounce. It’s like dumping buckets of water into your bathtub all at once and expecting it all to instantly go down the drain without making the water level rise near the drain. If you make your voltage = 0 datum for your measurement the drain lip everything will bounce up and down as you dump electrons down the little drain (by flashing LED lights). As you say what needs to be done is you need to provide lower impedance path as parallel to your Arduino for power and ground. A proper measurement system will have several ground and power networks that all eventually meet back at the power supply.

On a precision system you will likely need capacitive bypassing like you put in as well as inductive choking on your input power to your LEDs. This will isolate the power surges from the analog power going to your measurement system. Do a search on a pi filter for power conditioning. It’s just a few inductors and caps to kill transients.

A lot of the stuff you’re seeing is the result of the Maxim LED controller. Equal brightness is likely current balancing done on the controller. Less hardware issues are because wiring complexity is encapsulated inside the Maxim chip not on your breadboard. Noise because the Maxim chip really needs its own low impedance power and ground network. Read its data sheet, it’ll likely tell you how to provide power for it in a measurement system. Daisy chaining is easy and good for data but not good for power and ground. Use a star power/ground topology instead of daisy chains.

Not sure why you remove the reverse polarity diodes. Those are to keep you from blowing up your stuff which you will eventually do if you’re using flying leads. I’d only leave that diode out if the module was permanently soldered to a board. The minute you introduce plugs and cables somebody (you) will inevitably reverse polarity. It will just take one time and you’ll be back on aliexpress or you’ll be learning SMT soldering. I get it, nobody wants to lose 0.7v forward bias to the diode and get dimmer LEDs. The designer put it there to protect you.

The red acetate looks really good. Look at all pro systems. They have a red window. I designed a few red led displays early in my career. The red window really increases the contrast by preventing the white unlit dies from showing through. It blacks out the black backgrounds. The notch filter of the red window must be close to the LED wavelength. When it all comes together you get that 1970s eye popping look of seven segments. Six million dollar man stuff. My favorite way to DIY this is with color laser printed transparencies. (Pre power point pre Keynote). You can print nice rectangular windows and digitally blend red/purple/orange to get that perfect pass through filter. I think an inkjet would make good ones. Don’t forget to mirror the prints because you want the ink on the inside. I’ll try to dig up an example in my junk box. It was amazing what you could do with a color laserjet loaded with transparency and Illustrator.

ETA you can also find discarded trans red gift wrap or floral wrap