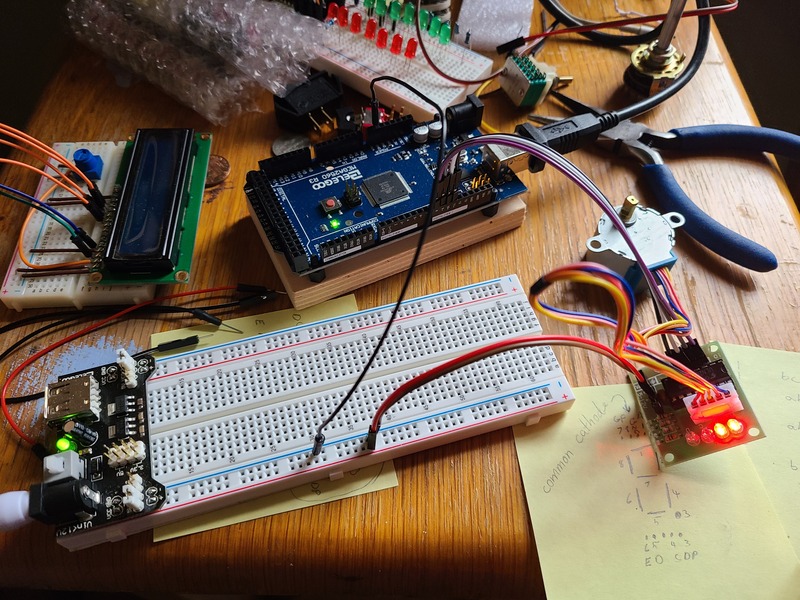

To start out, I hooked up the stepper motor from the Arduino starter kit (thanks again @Anesau) using the standard example here:jacob wrote: ↑Sun Oct 15, 2023 10:36 amI finally feel confident that I can build a CNC router + I have something to use it for.

My aim is to make this particular one: https://www.instructables.com/Homebuilt ... ased-GRBL/ ... using wood for all the components including the 3D printed ones. I want to hook it up to a dedicated Raspberry pi.

In the spirit of much increased synergy from making the same project, I invite people who are interested in making the same router to join me. It would be most helpful to be competent in at least one of the many skill components required. For example, given my background in mechanical clocks, I'm certain I can make all the wood+metal structures. OTOH, I know nothing about CNC programming.

To reiterate, the group strategy is to make the same widget. This will make it a lot easier to help each other. I would, for example, be able to make wood brackets for those who don't have access/skill to a scroll saw or a 3D printer, but this will only work if we're all making the same thing.

https://www.makerguides.com/28byj-48-st ... -tutorial/

It turns left and right in a very slow and convincing way. This is already halfway to building an Etch A Sketch with a sharpee. All it would require is a second motor ($1) + controller ($0.75) and a 2D gantry, alternatively hooking it directly up to the toy. I just might ...

The CNC router is only a difference of details and size.

I've been looking at starter kits, such as this one: https://www.amazon.com/dp/B072N4FMRN/

This seems to be one of those things, where lots of companies package a bunch of components together and sell them as a kit with some parts missing. For example, this one comes with 3 limit switches, but don't you need 6: One at each end of each axis?

It would be best if we all got the same kit. I've noticed that motors and motor controllers are slightly different.

Also TBD is:

1) What size wiring to use?

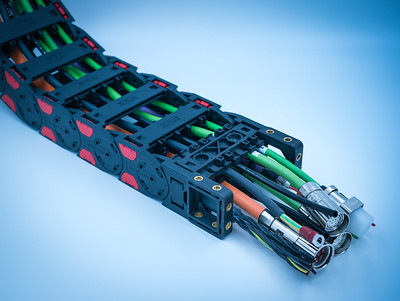

2) How to make a wiring harness that doesn't tie itself into a knot once things start moving?

3) What router to get? The router needs a relay to start/stop it from the Arduino ... or are they just always on?

4) The 3 nema17s need an external power supply (in the pic, the power supply is the black shield jammed into the protoboard). How big?

5) Where to get the metal rods?